Capacitor Grade

Tantalum Powder

Global Advanced Metals (GAM) produces three types of capacitor grade powder: Angular, Nodular and Flake.

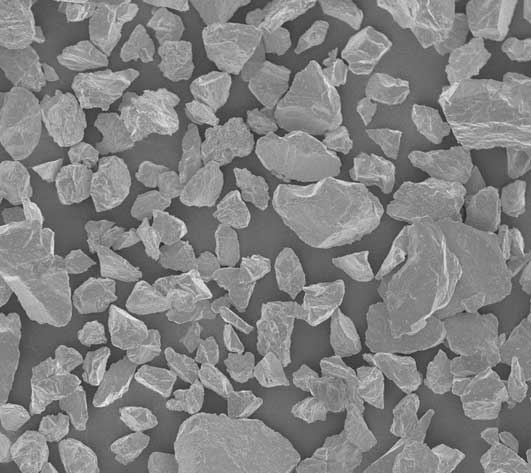

The angular or EB type powders are manufactured using an electron beam melting process. These powders contain both angular and flake shaped particles, which have been agglomerated to a specified surface area and capacitance range.

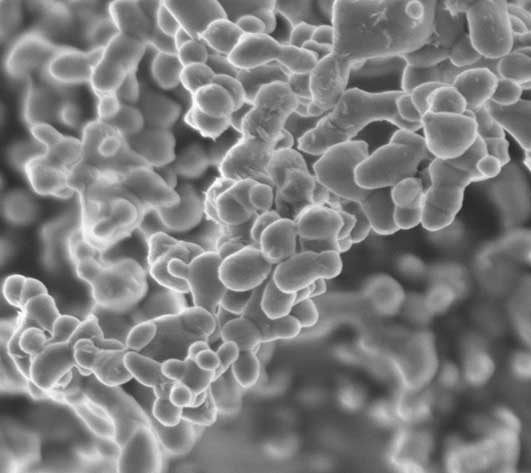

Both the nodular and flake type products are produced via a sodium reduction process. These products have high surface area and excellent handling and flow characteristics which allow capacitor manufacturers to produce small anodes with tight weight and capacitance tolerance.

GAM produces commercial powders with capacitance of up to 250K CV/g, and is developing new technology to take powders to 325K CV/g and beyond.

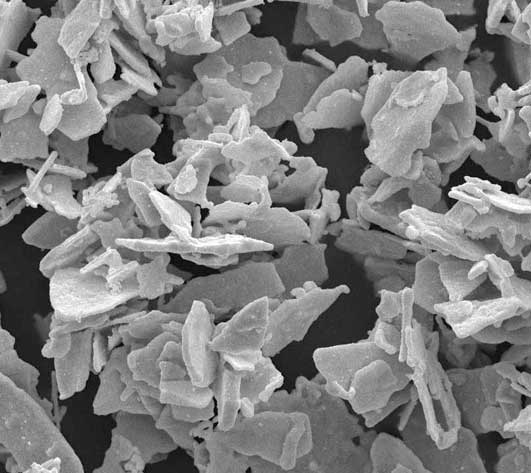

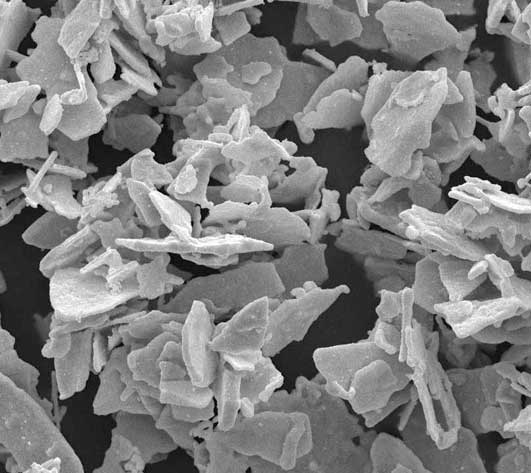

The flake product is unique to GAM. This powder type is manufactured using our patented process to generate a flake shaped product, which extends the capability range into mid-voltage applications.

Angular Powder

Nodular Powder

Flake Powder

Capacitor Grade Wire

GAM produces high purity tantalum (99.95% minimum) wire for use across many applications and specifically as capacitor wire. In capacitor applications the wire serves as the path from the anode to the circuit board.

GAM’s capacitor wire can be un-doped or grain stabilized and has followed the same ISO controlled process since 1993.

GAM offers capacitor wire in customized diameters from 0.15 mm – 0.50 mm and also available in three tempers:

- Annealed (Soft – Low Tensile Strength)

- Un-Annealed (Half Hard – Medium Tensile Strength)

- Un-Annealed (Hard – High Tensile Strength)

Metallurgical Grade Powder

GAM produces high purity metallurgical (met) grade powder up to 99.995% purity on a metal basis. These met grade powders are used across a broad variety of high reliability applications like electronics, aerospace, defense, military, medical, energy, space, chemical processing and others.

The high purity met grade powders produced by GAM are produced using a fully integrated and certified conflict-free supply chain and offered in two (2) different morphologies:

1. Angular which is produced via electron beam melting and has high purity, fully dense particles and a customizable particle size distribution.

2. Nodular which is typically produced via a sodium reduction process and has connected particles, a broader and fixed particle size distribution and used predominately in press and sinter applications.